There’s a ‘born again’ zeal of enthusiasm about cans amongst the craft beer fraternity; it’s intriguing and amusing. For years, brands of beer that put their product in cans were deemed in some way cheap or sold out. There was a lingering perception of ‘tinniness’ but also associations of ‘13½ Free!’ or ‘500ml extra value’ or even the faintly ridiculous pint cans that you still see in the UK, which seem to be tottering along on super high heels, just waiting to ‘do a Naomi Campbell’. It’s been a source of frustration for can makers for years and their industry body, which is imaginatively titled the ‘Can Makers’. Because, cutting through any of their potential bias, cans really have been a brilliant beer package for donkey’s years. They are incredibly light to transport (filled and unfilled); rugged, despite the incredible thinness of the can walls; efficient conductors of heat so they chill down quickly. And they are also flavour fast: the cans are lined with a food grade film which prevents any contact with the steel or aluminium walls and of course, no light is going to sneak through, eliminating the threat of light strike.

So it must be down to the craft brewers. They have stepped in and reversed the decline in cans’ perception, because otherwise, nothing is different.

Except, no. There are a few differences this time round. And it’s the craft brewers who have seized them.

The first is size. The craft brewers have embraced small cans – better, for the often more challenging styles of beer they’re brewing, but also, just a more enjoyable portion. 330mls are hand sized and the volume fits in a wider range of glassware; they’re less likely to warm up as you drink too (it’s gone). Truly, it’s always baffled me why UK beer consumers simply wouldn’t accept a can size in beer that is totally acceptable to them in soft drinks and totally accepted when they travel abroad. Different beer in a different pack – that seems to have done it.

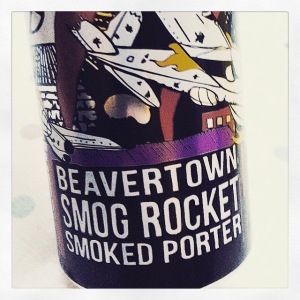

The second is finish. The craft brewers are embracing the material and its potential in a way that few of the more established players have done or are attempting now. More often than not, a brand’s design is simply ‘applied’ to the can and disharmony is the result (I know, been responsible for a couple myself). Where the design joins – tricky; the way the logo works with the curved face – a challenge. Brand owners and design agencies have broadly given up, resulting in something… just not right. But some of the craft brewers have said: how can we use the shape of the can to enhance our brand? To take it on and improve it? Beavertown is the notable example here: their cans are art, quite literally. There are no issues with worrying about facing them forward, as they can be faced anyhow and make a panoramic comic book shot working along the shelf. Magic.

And there’s feel too: varnishes and textured finished have been around for a few years, but it’s taken the craft brewers to use them to their potential. Why? Because they’re not scrimping for savings, worried about the added ‘on cost’. The value built into their inherent proposition allows them to buy slightly more expensive cans and reap the reward. Look out for stippled matt finishes and spot varnish. Little touches yes, but in the hand, they transform how the can feels and even – gasp – make you think about drinking from it.

But one issue is overlooked. Unlike bottling, canning your beer is a more serious financial proposition. Can lines aren’t cheap – and they’re certainly more expensive than bottling lines. They’re also a bugger to run – the tolerances compared with bottling are much tighter – think Formula 1 car vs rally car. Both high performance, but one takes it to another level.

And then there’s the cans. This isn’t like buying a run of labels for bottles: there’s no writing them off by popping the old labels down to the local recycling tip. Buying a run of cans is a major undertaking and if you buy them, by god, you use them. And finally, there’s a structural question. Whilst bottling lines are – broadly speaking – ten a penny, canning lines are something else. There are fewer of them; they’re largely fully employed and also, and this is a big issue if you brew 10 barrels a week, massive. There are whole canning lines dedicated to Coke. Not Coca-Cola’s range of products, just Coke. 24 hours a day. All year. Picture it: “’Scuse me mate, can we fit in a run of 8 Ball Rye next Tuesday?” “Er…. no”. So what’s happened? Well, the incredible thing is that some of the brewers have taken on the challenge and have bought canning lines. That takes big balls. Big balls of lead. But there’s beautiful commercial creativity too: there are operators now running mobile canning lines. They come to you. Fill. Clean down. Offski. That is brilliant.

And the even better news is that it’s just begun. Tinted was responsible for bringing thermochromic – temperature sensitive – ink onto cans 10 or so years ago. But 5 years from now, that is going to look – aptly you may feel – like very small beer.

© Beer Tinted Spectacles, 2015